ABOUT SJ Toolings

SJ TOOLING is a state of the art tool room being set up in the year 2018 by highly experienced professionals who have over 20 years of vast experience in designing, manufacturing and supply of precision plastic injection Moulds & Moulded parts.

Data study with mold design will be reviewed with the customer in order to receive the customer inputs and lessons learnt from their previous experiences with the similar parts.

OUR MISSION & VISION

OUR PHILOSOPHY

- One-Stop Solutions

- Competent Performance

- Timely Deliveries

- Safe and Healthy Working Environment

- Strict adherence to regional compliances, and labor laws

SJ Method Of Mould Making & product validation

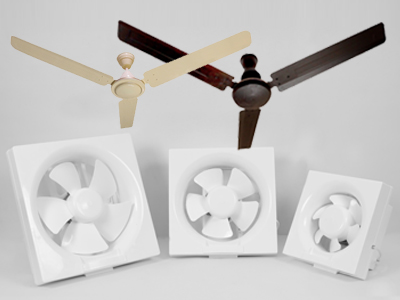

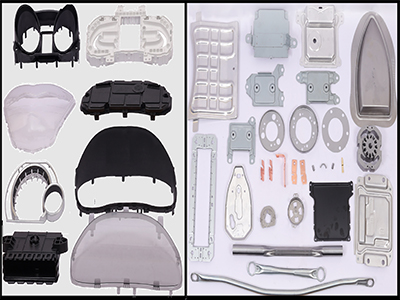

SJ specifically focuses on Functional parts and Aesthetic parts.

- Detailed Study of end product . (Specifications,fucntional requirements ,GD& T).

- For functional parts witness lines, weld lines, fitments. Based on this steel safe conditions are decided.

- Study of material, Grade , Rheology , mold flow and cool warp analysis .

- Defining the machining process based on the requirements.

- Designing the mold with proper care by which considerations are given for future corrections and improvements. Faster machining, proper care for aesthetics, Improved build quality ,longer life tools based on customer requirements.

- Data study with mold design will be reviewed with the customer in order to receive the customer inputs and lessons learnt from their previous experiences with the similar parts.

- Steel safe conditions for negative correction, closer tolerance dimensions.

- Planning inserts, pins for easy replacements and re machining easiness.

- Proper measuring and assembly techniques.

- Best quality oils, coolants. Proper surface treatments and usage of standard components.

- Usage of CMM for inspection based on requirements from a trusted vendor or suggested vendor.

- Mold trials and corrections until the pre agreed terms are met.